The Complexity of Wheelset Procurement

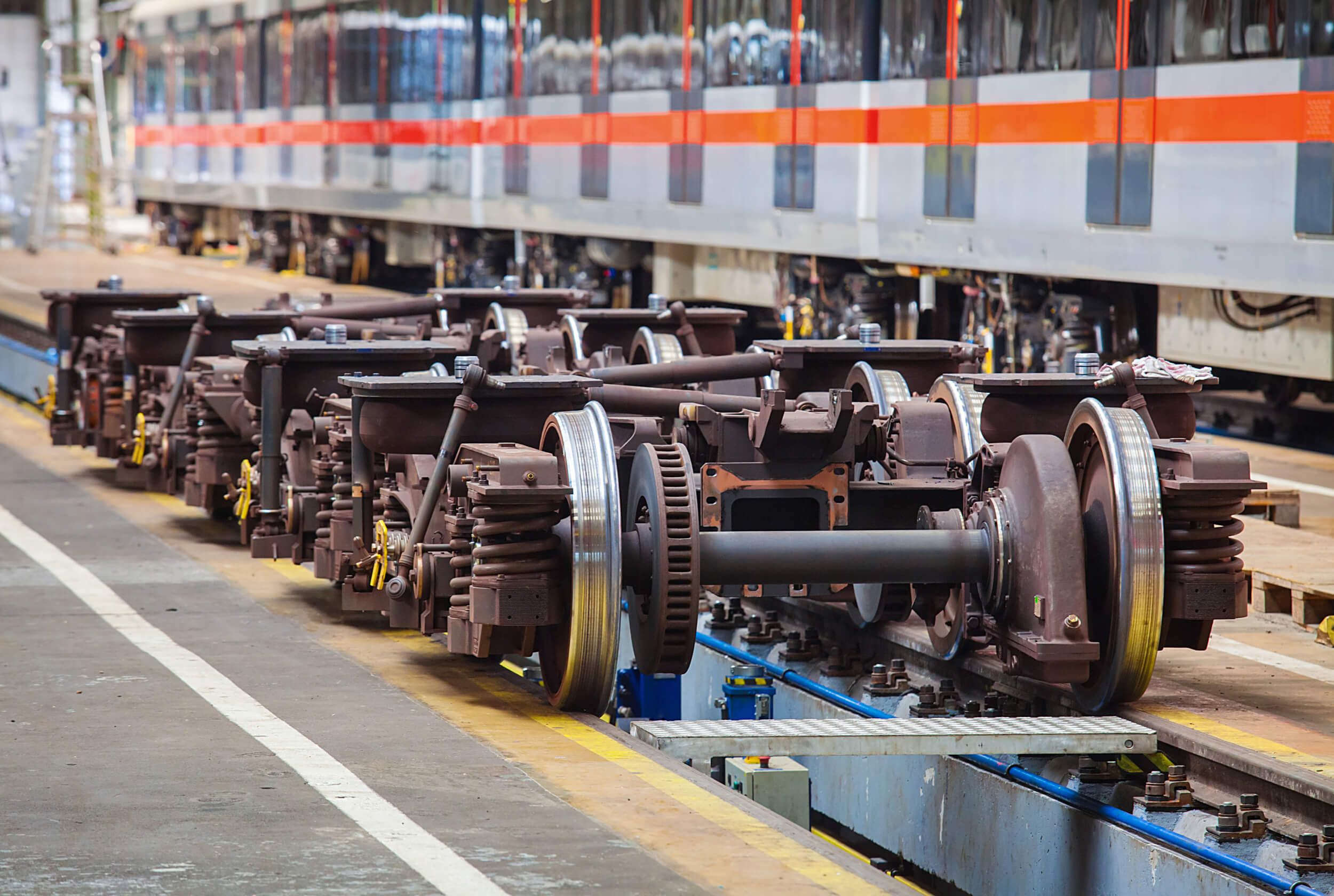

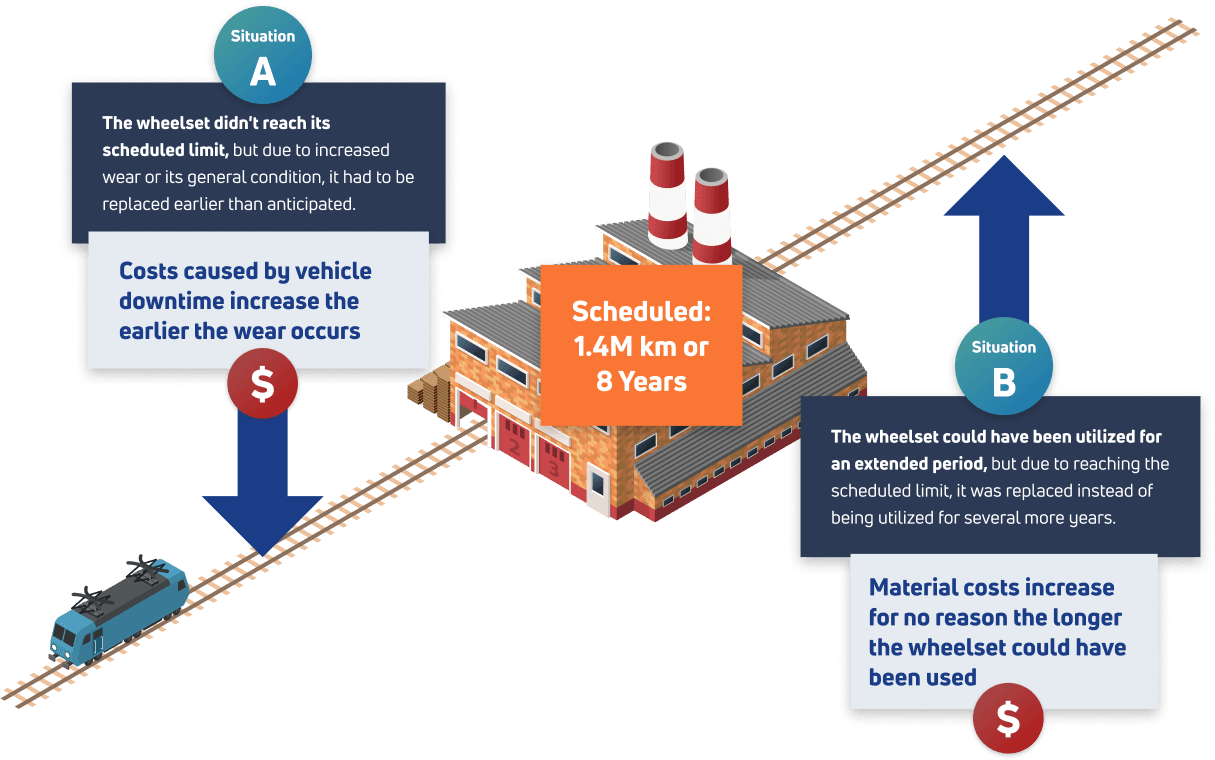

Wheelsets play a pivotal role in rail transport, both in terms of functionality and cost. Procuring wheelsets entails meticulous planning due to their extended lead times. Traditionally, such planning relies on distance or time parameters, often overlooking the nuanced wear patterns of wheelsets. Yet, wear is influenced by multifaceted factors like braking habits, age, and material composition, rendering it a highly intricate process.